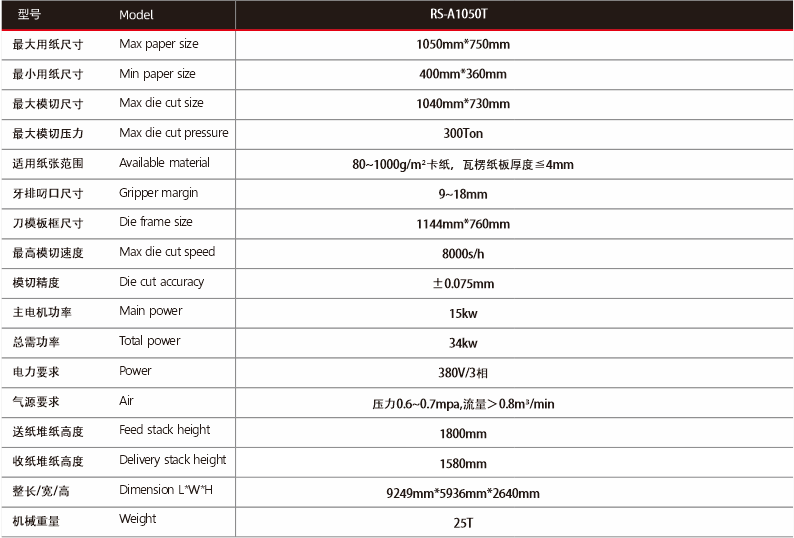

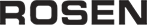

RS-A1050T Automatic Die Cutting and Creasing Machine With Stripping & Blanking

Features:

Using pliers to pick up the paper, it can ensure high-speed safety.

The special feder design can feed the paper correctly, and the feeder deceleration unit has two functions: nomal and deceleraion, which can beswitched arbitrarily.

The side positioning adopts a push-pull device, whidh is easy to switch and can be selected according to different paper types

Detection of doulble-sheet feeding and front positioning, side positioning, abnomal feeding, automatic shutdlown device.

Pneumatic locking system for die cut frame.

Die cutting pressure can be adjusted according to paper quality, up to 300 tons.

The upper and lower needling devices of the waste removal section is simple and easy, and it is equlipped with the secondary deaning and

removing the waste paper edge.

The feeder and stacker are equpped with non-stop devices to ensure uninterrupted producion.

Touch screen display system, including computenized automatic detecion device, provides operaton instrudions for each part and abnommal

elimination instructions.

Wide range of die cutting capadty from 80g to within 4mm of comgated paper

The allin-one machine is hoisted, the height of the whole madhine is increased by 300mm, and the pie of paper is increased by 25%

Full sheet delivery option to ensure easy production planning by selecting final delivery style.

Automatic separating sheet inserter oupledl with electronic position sensor at blanking station

The Sampling Function can be used to remove a sample sheet on the fly by one button only, easy for operating.

Feeder:

The design of the stacking preparation table has been improved. The preparation trolley can beused to pre-stack the paper, or the pallet truck can be used to directly send the stacked paper tothe main stacking table.

Adopt powerful four-suction and four-feed high-speed feeder, with stable and smooth paper feeding.

The high and low angles of the first suction and the second suction can be adjusted separately toadapt to the warping of different paper surfaces.

Imported patented spiral blowing device makes the paper deliver smoothly.Feeder double-beam type ensures stable and durable paper feeding.

Delivery:

Adopt Taiwan original pull and push dual-use side sheet registration system, which can be easilyselected according to different material.

The paper feeding belt is lengthened to ensure that the corrugated paper is fed smoothly and inplace.

Unique dual-purpose mechanism for thick and thin paper, which can be switched according todifferent paper, ensuring smooth conveying and positioning of thick and thin paper.

The paper feed roller quick adjustment mechanism is equipped with a weight balance device tofacilitate the adjustment and positioning of the paper more conveniently.

Die cutting:

Pneumatic locking system for die frame, is convenient and quick.

The two contact points of the front positioning paper stopper can be individually fine -tuned toadapt to precise positioning under different paper conditions.

Using advanced technology, the positioning of a single gripper can be fine-tuned before andafter compensation to meet the requirements of processing accuracy.

Electric eye monitoring throughout the work, with large-capacity man-machine interface LCDdisplay, providing detailed troubleshooting methods.

Equipped with an air-cooled circulating oil temperature cooling system to avoid the movement ofthe creasing strips on the bottom plate due to excessive oil temperature in the machine.

lmported hard die-cut steel plate, which is durable and not easy to deform.

Stripping:

Triple coordinated waste stripping device, precise and powerful, can effectively remove all kindsof shaped wastes.

Double-layer drawer type upper and lower waste removal molds can be quickly adjusted andchangeover.

The upper frame adopts electric control lifting device.

Various specifications of waste removal components are included, which can be combined.arbitrarily according to the die-cutting products, and the changeover is convenient and fast.

Different Product:

Quick lock system for parting tool

Pneumatic lifting device for upper frame of product

Constant leveling system (NTC, the top of finished products may warpage unevenness after stacking, canadjust the top surface height of finished products to increase or reduce the pressure

Automatic non-stop paper receiving device

Pull-out full clean waste products on the frame, fast version change, easy to operate

Waste edge output department:

Waste edge conveyor

Non-stop sampling device

Overview:

High-performance double beam paper feeder.

The vacuum pump is Sino-German Baker.

Pneumatic clutch is litalian brand, paper feeding electromagnetic clutch is imported from Germany brand.

The main chain of the gripper drive is a special specification imported from Germany lves/lWls.

The transmission chain of the mechanism is mainly imported from japan.

High-torque transmission belts are mainly imported from Germany.

The bearings matched with the mechanism parts are mainly imported from japan and Europe.

Precision mechanical parts such as high-standard transmission gears and linear cams are imported and assembled from Taiwan.

The whole group of high-precision locators are imported and assembled from Taiwan.

The whole machine's high-guality plastic steel rails, imported and assembled from japan.

The main machine inverter is imported from Yaskawa Japanese

The PLc controller is imported from Taiwan Yonghong.

Photoelectric switches are mainly lapan and Europe brands,

The touch screen for display monitoring and management is 15-inch Kunlun Tongtal.

The whole set of torque limiters are imported from Taiwan.

Safety control of automatic oil feeder, solenoid valve, etc. are imported from Taiwan.