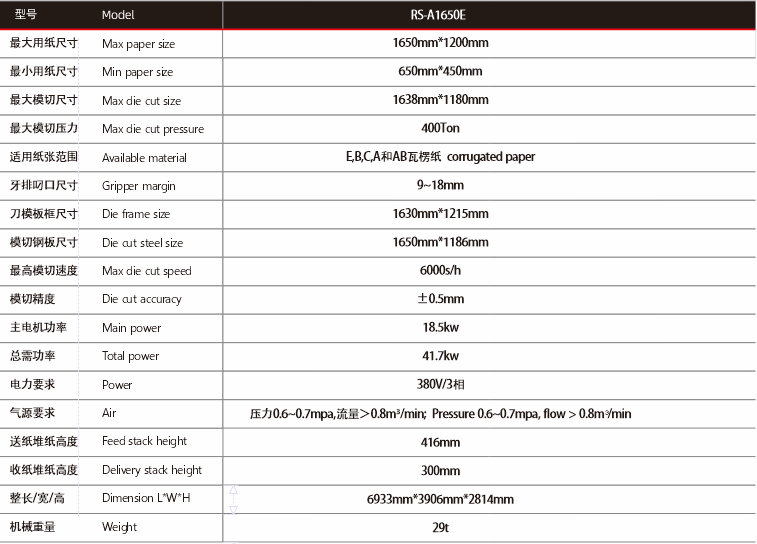

RS-A1650E High-performance automatic flatbed die cutting machine

Features:

◆Gearing wheel with optimized design and space facilitates higher engage precision with less friction noise;

◆Application of double-section-and-double-row chains to transfer and feed paper ensures better stability in each operation;

◆ Absolute sealing and dust-proof design decreases maintenance frequency and cost as well as raise the productivity;

◆ To utilize 30% less parts in the optimized index brings much more stable performance with less chance of fault;

◆ 10.4’ color touch screen operation panel gives total control of the machine and graphic display machine parameters, job setting, fault diagnosis and etc., more direct and operator friendly;

◆ The centralized lubrication system is easy to maintenance.

Feeder:

◆ Non-stop feeder with bottom nozzle using advanced technology

◆ The paper plate and front stopper are accurate, and the double-sheet detection device responds accurately

◆ Use vacuum adsorption method to feed the cardboard to the pressure roller, which is not easy to scratch the printing surface

Die cutting:

◆ The worm gear crank mechanism drives the toggle-type high-precision plane die-cutting lower worktable, reducing the power of the main motor by about 16% and reducing energy loss.

◆Die cutting department operation safety door and pneumatic plate frame safety locking system

◆Handle wheel-type pressure fine-adjustment device with gravity position indicator

◆The independently developed and designed large dynamic angle and high torque box-type cam intermittent mechanism makes the paper gripper row run more smoothly and reliably,

reducing dots and preventing the plate from loosening. It is also equipped with a reliable overload torque protection system.

◆The connection between the die-cutting knife plate and the die-cutting plate frame is in the form of grab nuts and screws, and a central positioning system is used when loading, making the plate change quick and accurate.

Stripping:

◆The fixed horizontal position cleaning template is combined with the progressive acceleration motion curve to remove waste and hit the waste point on the upper frame.

The cleaning structure is streamlined and the movements are reduced. However, the intensity of the waste point is instantly increased, making the waste removal action simpler and more effective.

◆Centrally positioned fast plate removal locking device and upper frame mold clamping system, fast plate change and easy operation

◆Adopting central positioning system, proofreading is fast and adjustment is easy

◆The front waste cleaning device can completely remove the waste material on the paper edge, and the waste material on the paper edge will be sent out of the machine by the conveyor belt.

The template stroke is increased and the movement curve is better

Piling and stacking:

◆The delivery department is equipped with an alarm system that will stop the machine immediately after detection personnel enter.Equipped with a paging counter (optional)

◆The mechanical cam driven paper delivery section is equipped with paper support, which makes the movement more reliable and accurate.

It is suitable for the requirements of panel die-cutting in various directions and makes the paper delivery more tidy.

◆The position of the side-aligned paper racket is electrically adjusted for easy and reliable operation.